Process Mapping

Investing in process improvement is a no-brainer, no matter your business size.

And I’m the expert to help you.

Process mapping and process improvement lead to increased operational efficiency. Identifying and eliminating unnecessary steps, reducing bottlenecks, and optimising workflow ultimately result in reduced costs, increased profit, higher customer satisfaction, and a more competitive edge in the market.

If you’ve arrived on this page, I’m guessing you are looking for someone to help you with process mapping or process improvement.

Processes may be your nemesis, but they are my passion.

My neurodivergent brain can spot problems or suggestions at lightning speed, and I can make impactful suggestions on what you can/need to do to improve the process.

I have over 25 years of experience improving processes in various companies, and I genuinely love it and am amazing at it.

“Investing in Becky’s support has saved me so much time trying to figure it all out on my own, as being super organised with ops and systems has never been my forte! If I hadn’t invested, I’d have probably still been in the same place that I was this time last year.”

Amy Burnett, Visible Impact (corporate video production business)

What is Process Mapping & Why It’s Important for Small Businesses

For bigger companies, they can also help to

Show the end-to-end process, which can be useful for large processes that span multiple teams/departments.

It can enhance cross-team working and relationships. People understand the bigger picture and how they contribute and can relate better.

They can help you find the problems, bottlenecks, and inefficiencies. As well as finding “wastage” that can include money, time, and resources.

It lets you see the current “as is” state and helps you plan “future” improvements. Where are we now, where do we want to be.

Assist you with monitoring and continuous improvement.

Process mapping is a visual representation of the steps in completing a series of tasks for a specific area of a business.

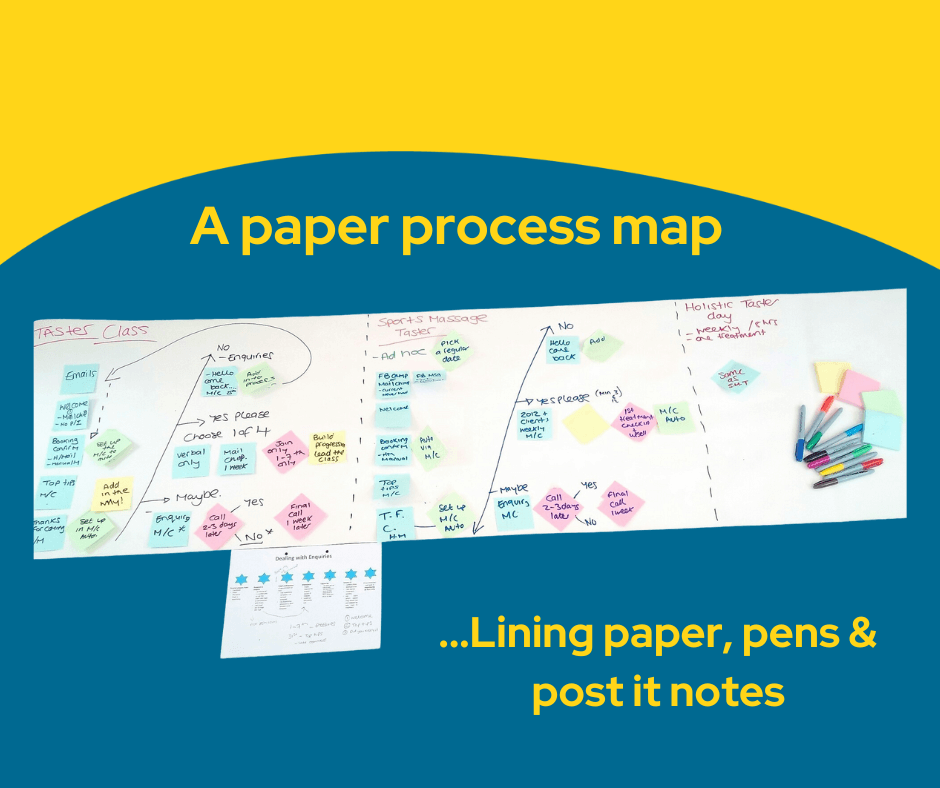

This can also be called a workflow and is represented in a flow diagram.

Depending on what you are documenting, the business type and size of the business (and other key factors) will determine how complex or simple your flow chart is.

The 3 key things that are normally documented are:

1. Inputs 2. Outputs 3. Steps

By outlining each step, small businesses can identify inefficiencies, redundancies, and opportunities for improvement.

Why do you need Process Maps?

Process maps provide information; they show the Who, What, Where, Why, When, and How aspects of the process (and problems) and can guide towards possible solutions or improvements.

These can be useful to small businesses for a number of reasons:

A visual representation that can be easier to read/digest

Ensure consistency - every customer gets the same service

Provide clarity - for your customers (and you!)

Enable you to spot problems, issues and inefficiencies

Help you to identify tasks that could be outsourced (or automated)

Help you to train others (staff or outsourced help)

How to do a simple process map

Rather get some expert help?

Identify the process you will map

Identify the start and the end

Map out the steps in between (Steps 2-9)

Mark any decision points

Identify any simultaneous process taking place

Identify any “waste” - aka issues (Use the acronym to help - TIM WOODS: Transport waste, Inventory waste, Waiting waste, Over-producing waste, Over-processing waste, Defects and Skills waste

Now, identify your improvements for each step

Review your map

Now map out your “future state.” This is your ideal process. It may be necessary to stage or prioritise it in high/low.

Finally - the hard work - do the improvements. This part should be formulated as a project and managed very closely with clear tasks, responsibilities, deadlines and ownership.

A real example of a £70,000 process problem I’ve solved

Let’s call this example - Business B. They wanted to invest in a new system, but to do that, they first needed to evaluate their current processes to understand exactly what they needed from a new all-in-one business system.

Here is a summary of the problems I identified:

There wasn’t a central source of “truth data” for the business

The whole customer journey wasn’t tracked and recorded and, therefore, was not easily reportable

Data was stored in multiple sources and was not linked nor dynamic (hello, spreadsheet chaos)

There were many “side processes” to compensate for the lack of a central data system (hello duplication and errors)

There were multiple convoluted processes, a lack of consistency and a lack of willingness to use and trust systems (hello time wasted, cross-team issues and process problems)

Communication and training improvements were also needed (hello, this is how we’ve always done it, that’s not my job and here’s a new system - use it)

Findings

After holding several detailed meetings, mapping the journey and analysing all the information, I made a very conservative guess that each staff member (10) were wasting/losing at least 3 hours a week due to the problems identified above. It would be higher in reality.

If you convert that into value (£), it was approximately a £35,000 annual loss.

This figure was on top of costly mistakes in another department due to not having up-to-date and key information in a central system. And the estimate was a further £35K. A £70,000 problem sat hidden in the business.